But, first things first, and before I even start with how do Air brakes work, I will give you few words on history of the Air brakes and move along from there.

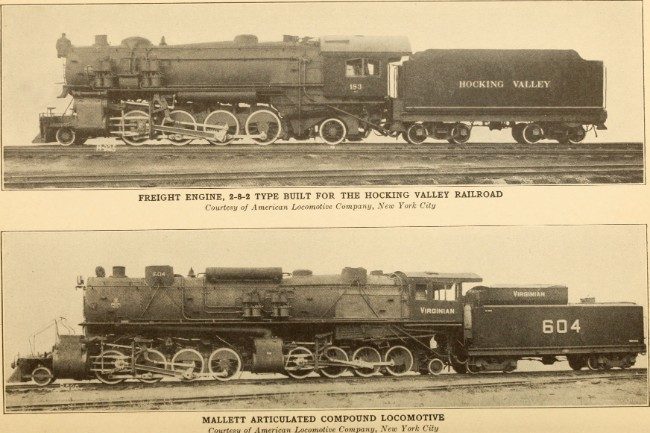

Before the Air brakes were born, the trains, buses and tractor trailers were using a primitive brake system.

For example the train break system was requiring an operator, or brakeman, in each car who will be there to apply a hand brake every time a signal was given from the train director/engineer! Can you imagine that hustle?

Of course you can’t! – Neither do I! But it was that way there for a while, until this inefficient manual system was replaced by direct Air brake systems.

These direct Air brake systems were using an air compressor to feed air through a brake pipe into the air tanks of each car. Then if/ when the engineer will apply the brakes, the pipe was filling inside with air and squeezing the brakes.