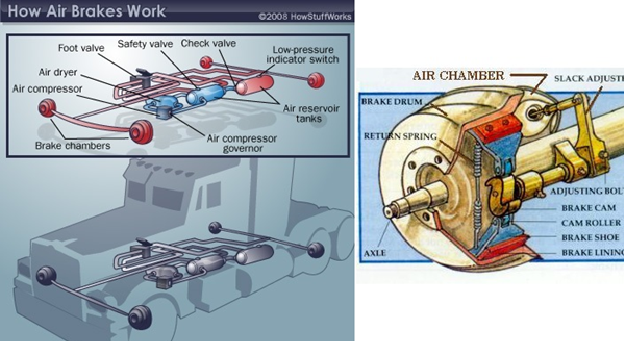

Driving a vehicle with a hydraulic system is totally different than driving a vehicle with air brake system because the air brake system needs to be monitored every moment for suspicious air leakage. You need to remember that the air pressure is the source of energy for your brakes to work.

LEARN 12 SECRET STEPS HOW TO MAKE $950 MORE PER TRUCK / MONTH

Hey! I'm George J.Magoci and I will send you a FREE eBook where you can learn 12 secret steps how to make $950 more truck/month.

The air brake system does not use hydraulic fluid to transfer the pressure from the brake pedal to the brake pads of the brake calipers, it uses air pressure and without required level of air pressure, your brakes won’t work.

Source: careertechonlineschool.org

Now you need to pay attention on this to be able to perform the CDL air brakes test in the right way.

- Put the seat belt on

- Start the vehicle and build pressure to 90-110 lbs

- To test the parking brake you need your engine to run, then apply parking brakes and put in gear. After you need to release the clutch slowly. After these steps are performed your truck need to stay stopped where it is (in the same position)

- Push one knob in and charge the air system

- Wait for the first fill

- Now you need to wait one minute to check for air leakage where the rate should not be more than 2 psi

- Apply 90 lbs pressure to the brakes and after that you need to hold for one minute

- The air leakage should not be more than 3 psi

- Pump the brake pedal until the light/alarm start on ; that would be in about 60lbs

- Keep to pump the brake pedal until the tractor protection valve pops out; that would be in about 20 to 40 psi

- Put your truck in a neutral position and test again how fast it will take for the air pressure to build up again. It needs to build 85 to 100 psi for less than 45 seconds.

- Continue to build up air pressure until air governor blows around 125 to 130 psi. You need to listen carefully for the air blow off sound

How to finish it successfully