Before the spring brakes, parking brakes were firstly supplied by a disk brake mounted on the drive shaft and rear service brakes were the best option. However, there was a problem when air pressure loss occurs. That’s why spring brake system became a must have option in today’s trucks.

But firstly, I will write about different brake systems and some specific braking processes. After that I’ll go to the details about spring brakes.

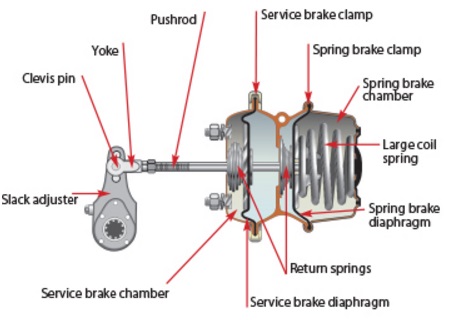

To understand the process, a driver should know the basic things about air pressure in braking. By pushing the brake pedal you control the air pressure. The air brake chambers convert air pressure force into mechanical push rod force.

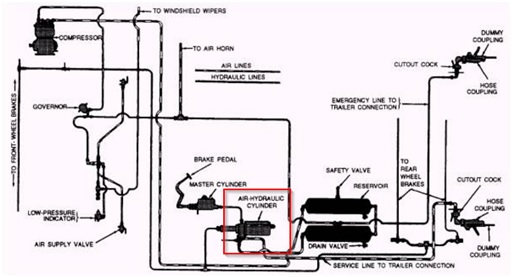

Air-over-Hydraulic Brake System

This system is combination of compressed air and hydraulic pressure use for brake operation. An air-over-hydraulic power cylinder contains both air and hydraulic cylinder, and they are fitted with a piston and common rod.

Because the air piston is greater than hydraulic, there is higher hydraulic pressure admitted to the air cylinder. So what this means for brake pedaling?